As India approaches the rabi season, the recent halt in speciality fertiliser exports by China presents both challenges and significant opportunities for domestic Indian fertiliser producers. While China has been restricting supplies of specialty fertilisers to India for the past 4-5 years, a complete halt impacts 80 per cent of specialty fertilisers supply for high-value crops such as fruits and vegetables, affecting agricultural belts in Maharashtra, Gujarat, Tamil Nadu, Uttar Pradesh and West Bengal.

An estimated 130,000-140,000 tonnes of speciality fertilisers were imported from China between June and December 2024 alone. Notable products include controlled-release fertilisers (CRFs) such as polymer-coated urea (PCU), chelated micronutrients (Fe-EDTA, Zn-EDTA, Fe-EDDHA), water-soluble fertilisers (WSFs) such as monoammonium phosphate (MAP) and potassium nitrate (KNO₃); and stabilised nitrogen fertilisers with urease inhibitors (NBPT). There are fears of price rises, as availability is not expected to be a major challenge. India has alternative import options from Russia, Jordon, and Israel; however, timely shipment arrival remains a concern.

Market scenario and growth drivers

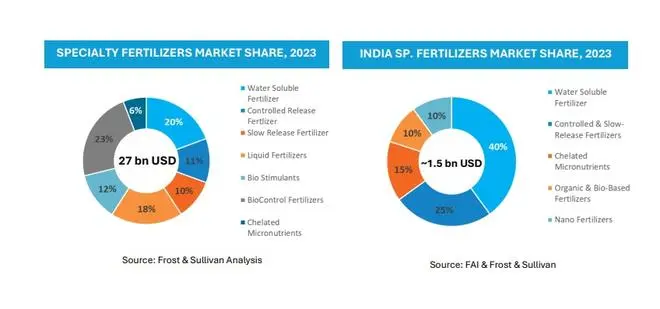

The Speciality Fertiliser Market has strong growth potential and is expected to reach $63 billion by 2035 globally, backed by sustainable agricultural practices.

Key growth drivers for speciality fertilisers

1. Nutrient efficient: CRF and SRF make the nutrients available for longer periods by reducing nitrogen loss via leaching, thus improving crop yield.

2. Environment-friendly: Delays denitrification by controlling the reaction of soil bacteria with nitrates

3. Water-solubility scarcity: Water-soluble fertilisers can be applied using drip irrigation techniques, optimising water usage.

4. Sustainability: The use of bio-stimulants reduces the amount of mineral fertilisers introduced into the environment, lowering pollution of soil, water and air.

There is a strong need for high-efficiency fertilisers. The implementation of speciality fertilisers is increasing across global market, including the United States, Canada, Brazil, Europe, India, China and Japan. This is due to the rising awareness about the benefits associated with speciality fertilisers as they are more efficient as compared to standard fertilisers. The use of speciality fertilisers with drip irrigated and other fertigation equipment helps farmers achieve better cost yields effectively.

Driven by increasing adoption of precision and sustainable farming practices, India’s speciality fertiliser market is projected to reach $5-6 billion by 2030, with a CAGR of 18 per cent from 2025-2030 – if the government’s aggressive subsidies and China+1 strategy are effectively deployed. However, the government’s subsidies do not always translate into higher industry value. For example, the Indian controlled-release fertiliser market saw a decline in market value despite increased consumption. The main reason was the Indian government mandating that all domestic urea producers manufacture 100 per cent neem-coated urea and distribute it at subsidised prices to the farmers.

Domestic players herald India’s self-reliance

China’s export halt is set to accelerate India’s self-reliance in speciality fertilisers. Domestic players such as IFFCO, Coromandel, Tata Chemicals, and GSFC are leading the charge, supported by government policies and R&D investments. The supply gap presents immense opportunities to domestic players across all segments of speciality fertiliser demand.

Controlled/slow-release fertilisers: India imported ~200 KTPA of PCU and sulfur-coated urea (SCU).

How are domestic players filling the market gap?

IFFCO’s Nano urea – A liquid nitrogen alternative reducing urea demand, Deepak Fertiliser’s Nitroplus® – Neem-coated slow-release urea; new start-ups developing lignin-coated urea for delayed nutrient release.

Chelated micronutrients: India imported ~50 KTPA of Fe/Zn-chelates.

Coromandel International – Expanded Gromor micronutrient production; GSFC & Aries Argo – ramping up EDTA/DTPA chelates. However, the local production of Fe-EDDHA is still a challenge due to high-tech requirements.

Water-soluble fertilisers (WSFs): Disruptions in supplies of MAP & KNO₃ for fertigation.

Tata Chemicals is scaling up hydroponic-grade fertilisers; Chambal Fertilisers is increasing soluble NPK blends. New JVs with Israeli firms such as Haifa Group for advanced WSFs are on the horizon.

Organic and bio-based fertilisers: While not halted, reduced the imports of humic acid and seaweed extracts.

Aquagro & Biostadt are expanding organic soil conditioners; Camson Bio is producing microbial biofertilisers.

On the technology front, IFFCO and KRIBHCO are leading innovations in nano-fertilisers, while Biostadt and Aquagro are scaling up for Bio-stimulants & precision agriculture solutions.

Conclusion

The Indian speciality fertiliser market is diversifying rapidly, with CRFs, WSFs and nano-fertilisers driving growth. Government initiatives and China’s export curbs are accelerating domestic production, albeit challenges such as Indian speciality fertilisers remain 10-12 per cent costlier than Chinese ones.

The technology gaps in Fe-EDDHA & advanced CRFs require foreign collaboration, for which there are 100 per cent FDI initiative by the Government. Meanwhile, alternatives from Israel’s Haifa Group, Morocco’s OCP Group, Belgium’s Solufeed and Germany’s BASF, are being considered for products including – Polymer-coated urea, Fe-EDDHA/Zn-EDTA, Monoammonium phosphate (MAP) and NBPT-treated urea.

China’s export halt has acted as a catalyst for India’s self-reliance, powered by PM-PRANAM scheme and diversified trade partnerships. However, niche specialities such as high-purity Fe-EDDHA remain difficult to replace entirely.

Balan is Associate Partner and Awalla is Consulting Manager, Chemicals Growth Advisory, Frost & Sullvan

Published on July 13, 2025